When we talk about the import-export sector of a nation, it’s not just the goods that matter but also logistics that play a key role. This field covers transportation, warehousing, inventory control, order fulfillment, and supply chain management. It has a significant impact on economic growth and performance. It cuts down production and transportation costs. It also boosts productivity by ensuring on-time delivery. India faces several challenges in managing its supply chains. These include poor infrastructure outdated methods, legal issues, shortage of skilled workers, environmental concerns, problems with last-mile delivery, and growing demands for clarity and traceability. To address these issues, India needs to upgrade its infrastructure and embrace new technologies.

India ranks 38th in the LPI (Logistics Performance Index), while China ranks 19th. One of the most important areas that China has mastered and India severely lacks is its railway network. The freight trains in India move slower than an average bike on the road. Its 25kmph. The major rail lines connecting metropolitan cities are oversaturated and work at 115 to 150% of their capacity and that too on the same tracks as the passenger trains. Whenever there is any clash between the schedules of these two, preference is always given to the passenger trains which results in a delay of 2-3 days for the freight trains. Thus, where an Indian train requires 60 hrs to move 1500km, it takes only 33 hrs for a Chinese freight train which travels at its lowest speed of 45kmph. Therefore, when an Indian trader can complete 146 cycles in a year, it is 263 cycles for China and the outputs create a huge difference in its profit shares. So now if we consider $20 million profits per cycle, for an Indian trader that would amount to $2.92 billion while a Chinese trader would make a profit of $5.26 billion! That’s an 80% difference in profits.

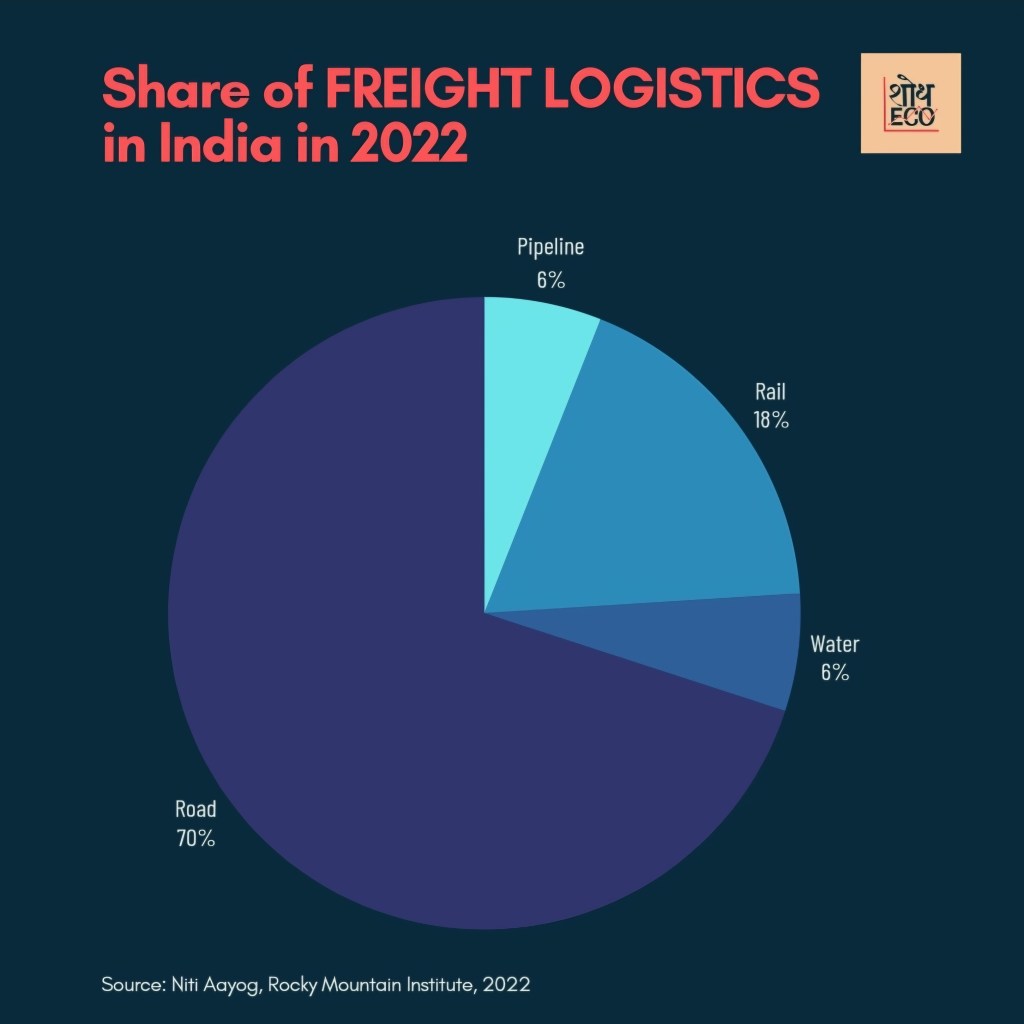

So when there is a huge gap in profit the Chinese vendor can easily give discounts and sell their products at a much cheaper rate. This is the difference that a freight speed change of 20 km per hour can make on the profits of the company and the trade competitiveness of two countries of the same product market and same product cost. While it costs 2.5 rupees per ton per kilometer by road it is just Rs.1.36 by rail. So, the rail is 83% cheaper than the road. And because today we use roads where transportation costs are very high. In India, the logistic cost is at 2.5 to 3.5% of the sales cost whereas it is only 0.8 to 1.5% globally. Also, trucks emit 6 times more CO2 than rails.

Conclusion:

The proposed solution for this is the dedicated freight corridors and the national logistics policy which will focus on developing tracks for cargo trains enhancing its speed and timely arrival of trains. It would focus on features like Integration of Digital System (IDS); Unified Logistics Interface Platform (ULIP); Ease of Logistics (ELOG); and System Improvement Group (SIG). It aims to create a smooth, efficient, and eco-friendly logistics network using the best technology. It is aiming to build 6 such special lines in the country. Simply due to the decongestion of roads along the highways, India will save 4.9 billion rupees in logistic costs. Few of its effects are already visible. All the shipments of LPG are transported by rail. The ports are directly connected to the freight corridor by a dedicated railway line which was earlier done via road. It has significantly saved time, costs, and manpower.